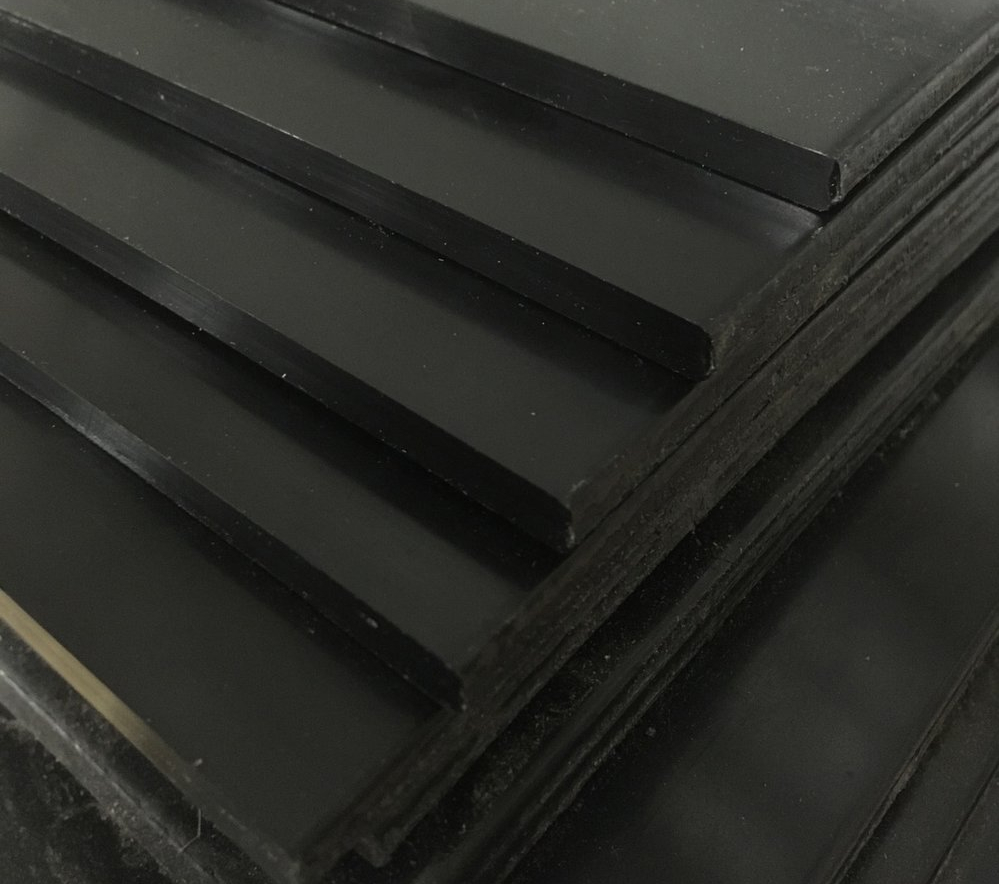

Mechanical Properties of HDPE Material

- Tensile Strength: HDPE can withstand considerable force, with a typical tensile strength of around 25 MPa. This property ensures that material can handle tension without breaking.

- Elongation at Yield: With an elongation rate of about 9% at yield, it offers flexibility under stress.

- Modulus of Elasticity: The modulus of elasticity in tension stands at approximately 1000 MPa. This one indicates that HDPE is able to deform under tensile stress.

Thermal Properties

- Glass Transition Temperature: It has a low glass transition temperature of around -95°C, which helps it remain flexible under extremely cold conditions.

- Melting Point: The material softens around 130°C, useful in thermal forming processes.

- Service Temperature: It is effective within a service temperature range of -30 to 90°C, works well in various climates.

Electrical Properties

HDPE also offers excellent insulation properties, which makes it suitable for electrical applications:

- Dielectric Strength: With a dielectric strength of 50 kV/mm, HDPE can resist high voltages, making it ideal for insulating electrical components.

Other Relevant Properties

- Impact Resistance: HDPE’s resilience is highlighted by its high impact strength, ensuring durability against mechanical shocks.

- Water Absorption: It exhibits minimal water absorption (<0.05%), which prevents swelling and maintains integrity in moist environments.

- Chemical Resistance: The material is resistant to most acids, alcohols, and bases, making it suitable for containers and pipework in chemical processing.

Below is a table summarizing some of the typical properties of HDPE:

| Property | Unit | Value |

|---|---|---|

| Tensile Strength | MPa | 25 |

| Elongation at Yield | % | 9 |

| Modulus of Elasticity in Tension | MPa | 1000 |

| Glass Transition Temperature | °C | -95 |

| Melting Point | °C | 130 |

| Service Temperature | °C | -30 to 90 |

| Dielectric Strength | kV/mm | 50 |

| Water Absorption | % | <0.05 |

Get in Touch With Legacy HDPE

HDPE’s extensive range of properties can be tailored to meet specific needs, which maks it a highly adaptable solution for a myriad of challenges. Whether in consumer goods, industrial applications, or infrastructure projects, HDPE continues to be a dependable choice for engineers and designers alike.

If you are looking for high-quality solutions tailored to the specific requirements of your HDPE boat production, contact Legacy HDPE. We prioritize quality and customer satisfaction, ensuring durability, efficiency, and cost-effectiveness. For more information about our products and services, please contact us directly at Tel: 307-299-3049.