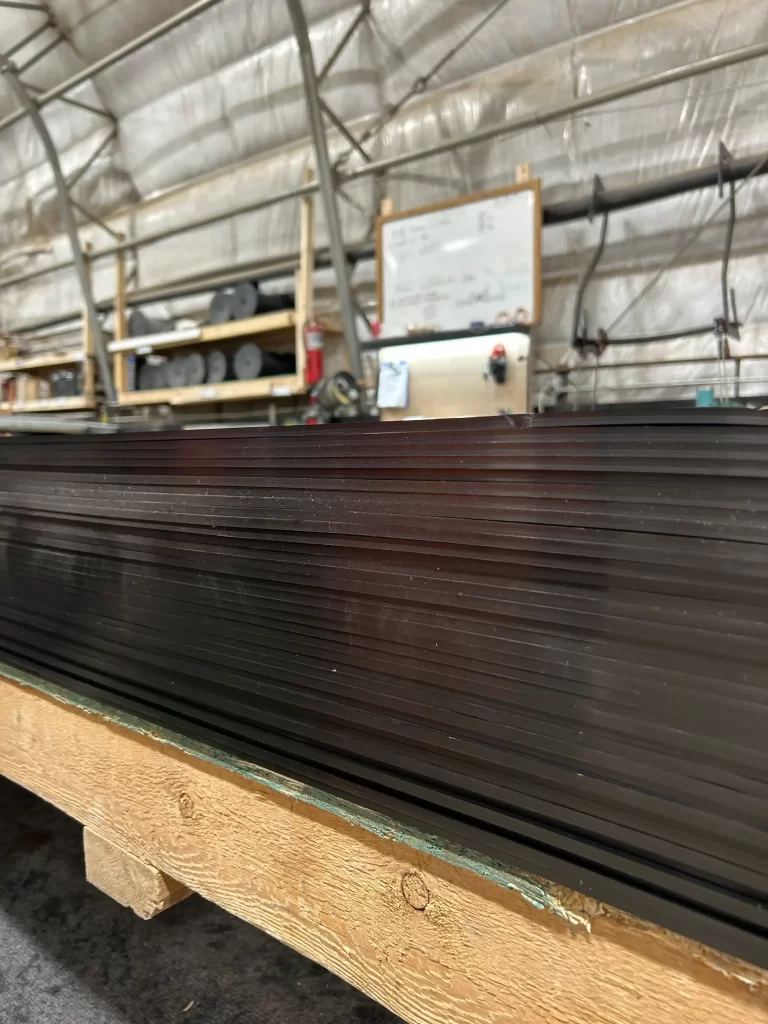

What are the primary benefits of using HDPE sheets?

HDPE Plastic is approved by the USFDA to hold food, allows for easily handlable texture, and is entirely reusable, moldable, and easy to work with. HDPE is a wonder plastic.

HDPE (High-Density Polyethylene) stands out for its remarkable flexibility. Despite its high melting point, which keeps it rigid at elevated temperatures, HDPE can be easily shaped once melted. This makes it perfect for various products such as cutting boards, milk jugs, detergent bottles, food storage containers, corrosion-resistant piping, geomembranes, and plastic lumber.

This material is extremely resistant to mold, mildew, and rotting, making it an excellent choice for underground water pipes. HDPE’s durability and resistance to weather conditions also allow it to be boiled for sterilization, which is ideal for food and beverage containers. Additionally, it withstands most strong mineral acids and bases, as well as naturally occurring chemicals in soil, and is almost impervious to water, solvents, acids, detergents, and cleaning fluids.

Despite having a density ranging from 0.93 to 0.97 g/cm³, slightly more than LDPE (Low-Density Polyethylene), HDPE’s linear structure with minimal branching offers superior intermolecular forces and tensile strength. This enables a lightweight HDPE container, weighing just 60 grams, to hold over a gallon of liquid or about eight pounds.

HDPE’s recyclability is one of its key advantages, helping reduce the amount of non-biodegradable waste in landfills and cutting plastic production by up to 50%. This makes it a cost-effective and environmentally responsible material choice.