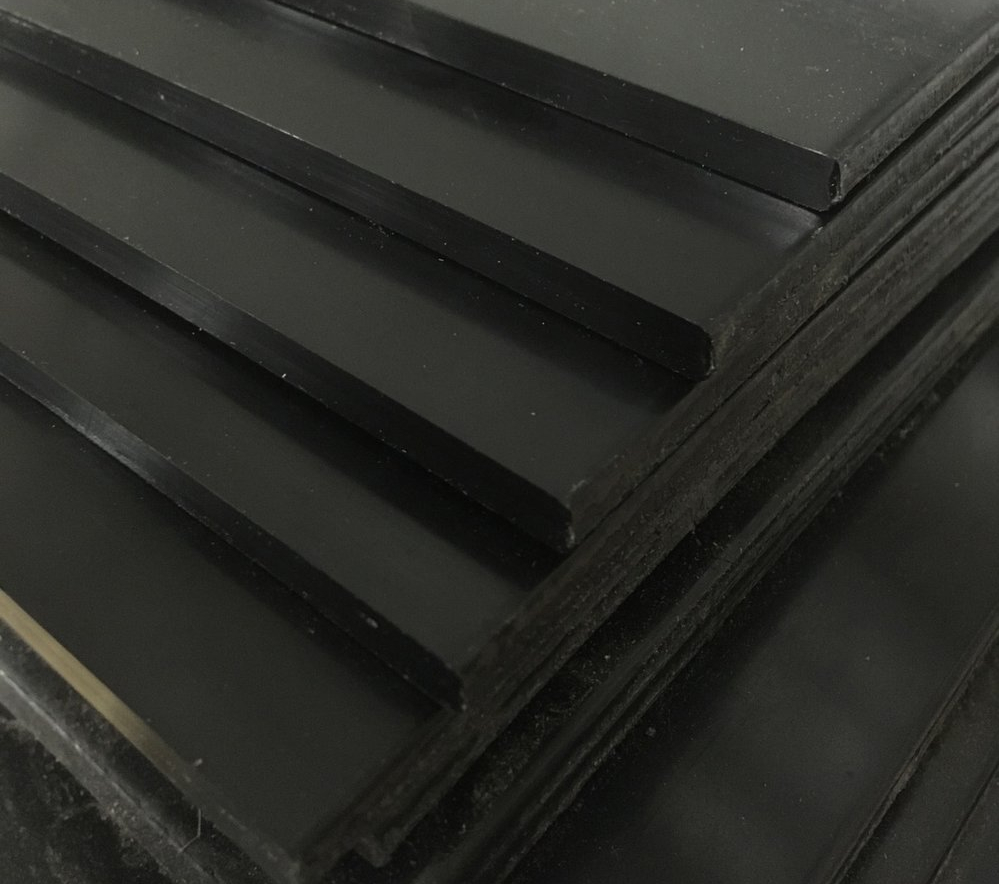

High-Density Polyethylene (HDPE) is a highly versatile thermoplastic known for its excellent temperature resistance. This characteristic makes it a favorite material in many industries, such as plumbing, food storage, and the marine industry.

Understanding temperature limits of HDPE material helps manufacturers and engineers tailor it for specific applications, such as building durable HDPE boats.

Temperature Resistance of HDPE

High-density polyethylene (HDPE) is known for its ability to withstand a significant range of temperatures, setting it apart from other plastics. As detailed in Andrew Peacock’s “Handbook of Polyethylene: Structures, Properties, and Applications” HDPE remains intact at temperatures as low as -50 degrees Celsius (-58 degrees Fahrenheit) without becoming brittle. HDPE’s structure is beneficial for products such as coolers and freezer bags, and it is also used in the construction of HDPE boats that can withstand harsh weather conditions.

On the higher end of the temperature spectrum HDPE handles up to 50 degrees Celsius (122 degrees Fahrenheit) and can tolerate spikes of up to 80 degrees Celsius (176 degrees Fahrenheit) briefly without losing its shape. Moreover, it thrives in extreme temperature conditions. For instance, marine vessels benefit from its stability in fluctuating temperatures. Additionally, HDPE performs well in areas with intense sun and cold storage. Its ability to handle extremes makes it a versatile industrial material. Consequently, it ensures durability and reliability across various environments.

The melting point of HDPE

The melting point of High-Density Polyethylene (HDPE) is a crucial aspect of its application. According to the “Polymer Data Handbook” by Oxford University Press, HDPE begins to melt at approximately 130 degrees Celsius (266 degrees Fahrenheit). This characteristic defines the upper threshold of its performance in high-temperature environments. The ability of HDPE to melt at this temperature is advantageous for its recyclability and adaptability. It can be easily reprocessed and transformed into new products, a feature that is particularly valued in the recycling industry.

Practical Applications and Considerations

Given its temperature resilience, HDPE is an ideal material for many industrial applications, including:

- Piping systems: Used extensively for hydraulic, gas, and water pipes due to its leak-proof properties.

- Storage containers: Suitable for containers and bottles that need to withstand low and high temperatures.

- Outdoor furniture and HDPE boats: Capable of withstanding various weather conditions without degradation, making it perfect for outdoor furniture and boat manufacturing.

Takeaway:

In conclusion, HDPE’s temperature limits make it a robust and adaptable material for demanding applications. It plays a key role in plumbing and food storage industries. Additionally, HDPE is emerging in the boating sector due to its temperature resistance. Whether facing -50°C in winter or 80°C in summer, HDPE remains reliable. Understanding its thermal properties helps companies innovate with durable products.

As industries push HDPE’s boundaries, its temperature capabilities will drive advancements. For HDPE boats and related products, the material ensures longevity and resilience,

Did you find this information useful? Link us at your page!

Learn more about our company: Legacy Innovation

Tel: 307-299-3049