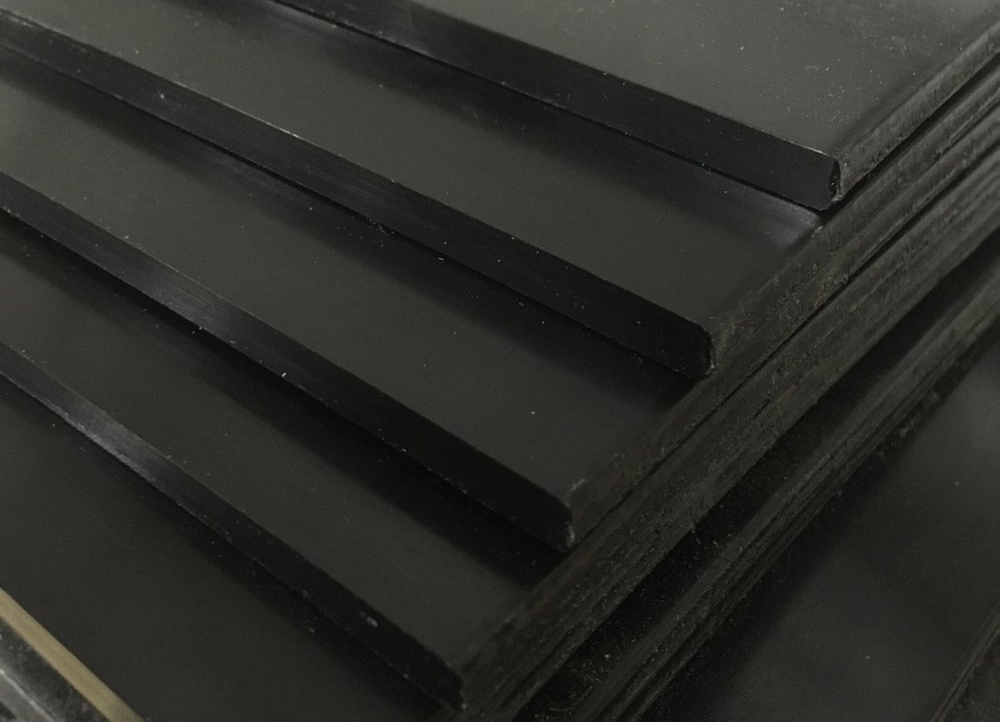

To ensure excellent quality and consistency, HDPE Plastic Sheets are manufactured in a series of processes. We have organized some important information to help you better understand how the procedures take place. In general, you will find everything from the preparation of the material to the preparation and finishing processes. If you need more information, you can contact us directly at the end of the article.

Preparing the Raw Materials

The production process begins with the selection of HDPE resin pellets. Moreover, these pellets must be selected by a specialized team, which is why we always buy from reputable suppliers. In fact, the resin always undergoes quality inspections both before and during use.

Extrusion Process: Melting and Shaping

The main technique for producing HDPE sheets is extrusion. To put it simply, these procedures, which include several important phases, are explained to you in details as follows:

- Melting: Using an extruder machine, HDPE pellets are heated and then we compress into a liquid state.

- Mixing: To tailor HDPE for certain uses, it’s possible to add optional additives like colorants or stabilizers.

- Shaping and Cooling: To create sheets with the proper thickness and width, HDPE is melted and then pushed through a die. Besides, to preserve their shape and hardness, the sheets are quickly cooled.

Sheet Finishing and Customization

Once manufactured, the HDPE sheet is cut, treated and finished according to our customers’ needs. Because HDPE is a flexible material, we can form the most varied shapes. For your information, the customization process happens as follows:

- Operators cut sheets to particular sizes.

- Surface treatment is added. The options for this service include sanding, polishing, and embossing, they all improve both look and functionality.

- Edges are smoothed or rounded to provide a safe and polished appearance.

Advanced Manufacturing Technologies

Technology comes to the rescue and specialized methods are used to improve the quality of HDPE sheets. In this case, as part of the process, extruders with precise temperature control, cooling mechanisms and monitoring sensors contribute to efficient production and reliable results. As mentioned before, our product quality is taken seriously.

Shaping HDPE Sheets

In addition to the extrusion process, other methods can be used to obtain more complex shapes of HDPE sheets. They are specified below:

- Thermoforming. In simple terms, this process involves heating and molding the sheet over a mold.

- CNC machining. This method is more technological and involves the use of computer-guided equipment to achieve accuracy in cuts and shapes.

Get in Touch With Us

If you are ready to invest in high-quality, long-lasting HDPE plastic sheets for your next project, please notice. Here at Legacy HDPE we offer carefully made sheets that are designed to fulfill a variety of industrial requirements. Contact us today to see how our products can boost your job and withstand the test of time!

For additional information, feel free to reach out to us at 307-391-0731. We’re here to help!