Among the most widely used and adaptable thermoplastics worldwide is high-density polyethylene, or HDPE. Its excellent strength-to-density ratio makes it the ideal material in sectors ranging from packing to construction. One of the criteria that distinguishes HDPE’s performance in diverse applications is its melting point. In order to fulfill market expectations, this article discusses the significance of HDPE’s melting point and its ramifications for industrial uses.

What is HDPE, and why does the melting point matter?

HDPE is a polymer derived from the natural black gold; petroleum. It is noted for its great resistance and stiffness to impacts and chemical action. HDPE’s melting point normally varies from 120°C to 180°C (248°F to 356°F), however these values vary according on its molecular structure and crystallinity.

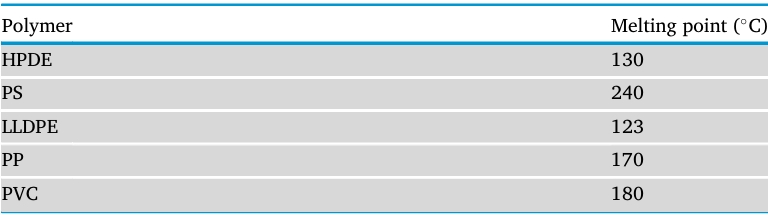

In greater detail, the melting point is the temperature at which HDPE changes from a solid to a liquid state. Knowing this transition correctly ensures good processing techniques such as injection molding and extrusion. Below you can see a table by scientists Abdallah and Rehab of polymers and their respective melting points.

Table 1- Melting points of different polymers.

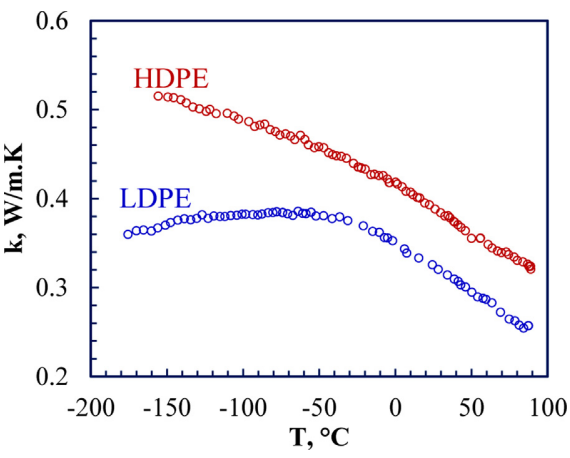

We can also observe the differences in conductivity due to the effect of temperature in the work of Eiermann and Hellwege. They compared the effect of temperature on the thermal conductivity of Low Density Polyethylene and HDPE. In their conclusions, it was noted that the melting temperature for HDPE is lower and it is a more stable material. LDPE, on the other hand, increases slowly with temperature at first and then decreases. The initial slow increase with temperature for LDPE was attributed by the researchers to the separate contribution of the amorphous regions.

Fig. 1 – Effect of temperature on thermal conductivity of LDPE and HDPE

Leveraging HDPE’s Melting Point in Pipe and Boat Strategies

HDPE’s melting properties make it an excellent material for pipelines and boats. In plumbing systems, thermal stability assures that HDPE can withstand hot water, industrial fluids, and geothermal applications without deforming. For boats, HDPE’s high melting point prevents warping under sunshine and high ambient temperatures, assuring endurance in severe maritime settings. Its capacity to preserve structural integrity under heat decreases the need for maintenance, making it more cost-effective for long-term usage.

In all industries, HDPE’s melting temperature plays an important role in its performance, providing a mix of strength and resilience.

In Summary

The melting point of HDPE is more than just a technical characteristic; it is an important consideration in material selection and ultimately performance. If you are looking for HDPE solutions, Legacy HDPE products are a solid alternative for you. We provide high-quality materials to meet our customers’ needs. Explore our website to learn more about the latest advancements in HDPE boats and pipes. For more information about our products and services, please contact us directly at Tel: 307-391-0731